Our Usage and Experiences with AVL Simulation Software

by Eriknem

Last year, we were fortunate enough to receive advanced simulation software from well-established engineering company AVL List GmbH - one of the world’s leading mobility technology companies for development, simulation and testing in the automotive industry. The cooperation was facilitated through the AVL University Partnership Program. This suite of tools is aimed to enrich our educational and research endeavors, offering our students and institute a comprehensive platform for automotive-focused simulation.

Tools include:

AVL CRUISE™ M - versatile simulation platform for vehicle system development, incorporating real-time subsystem models and an efficient solver for multi-physics simulation. It supports third-party tools (FMI) and enables model reuse from concept to real-time testing.

AVL FIRE™ M - cutting-edge 3D multi-physics simulation tool for next-gen powertrain and vehicle tech, offering advanced grid and solver technologies. It simplifies complex multi-physics analysis for various electrical components like batteries and e-motors, accessible to non-experts.

AVL VSM™ - comprehensive vehicle simulation package that streamlines vehicle development from concept to testing, enhancing attributes like efficiency and driveability through precise simulation and easy parameterization tools. It aids in balancing efficiency with driving pleasure, simplifying calibration and validation, and reducing prototype needs.

AVL CONCERTO 5™ - versatile, open data analytics platform equipped with domain expertise, ideal for engineers handling big data. It enables effective data visualization, analysis, and reporting, supporting customization to derive actionable insights from development data, regardless of time and location.

Diploma Thesis in vehicle dynamics

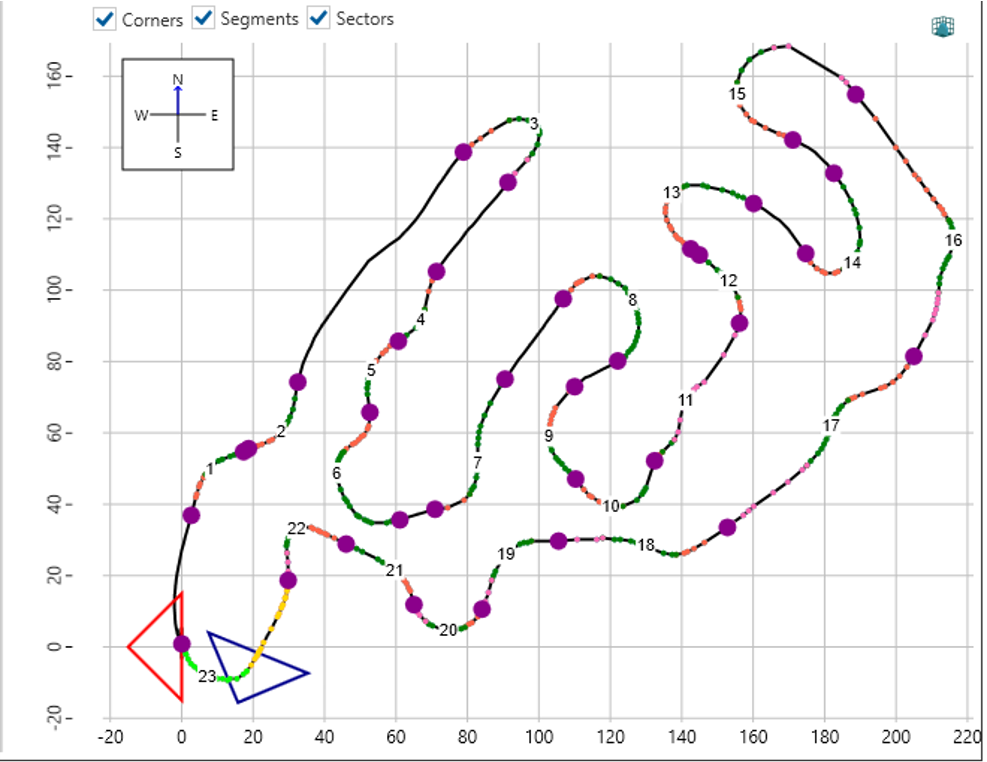

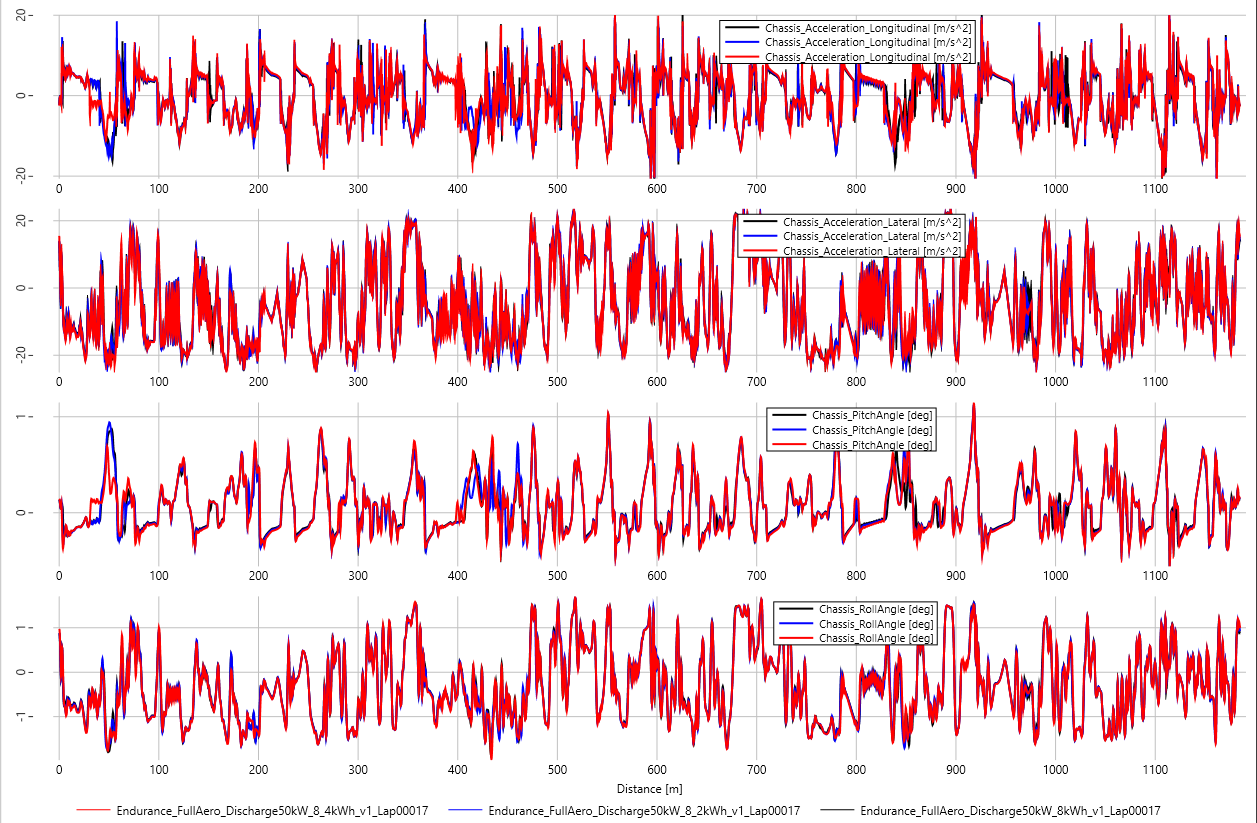

One of the possible applications of these tools was demonstrated in a diploma thesis by one of our students, Ing. Marek Humeník, utilizing the VSM™ vehicle dynamics software. The project focused on analyzing various configurations and parameters of an electric racing car developed by our Formula Student team, STUBA Green Team.

By meticulously parameterizing vehicle components such as powertrain or tires, the student embarked on a comparative study of different battery sizes and aerodynamic setups on a simulated racing track.

The objective was to identify an optimal vehicle setup, aligning the simulation results with the actual performance of similar vehicles on comparable track. Various different comparisons and evaluations were created, analyzing the ideal setup of the vehicle very well.

The findings from the simulation matched performance of other Formula Student teams driving the track in real world with good correlation, underscoring the precision and relevance of AVL's software for practical automotive engineering projects, even without huge effort and time investment. As a new software for our institute and the student, the VSM™ showed its user-friendliness and steep learning curve.

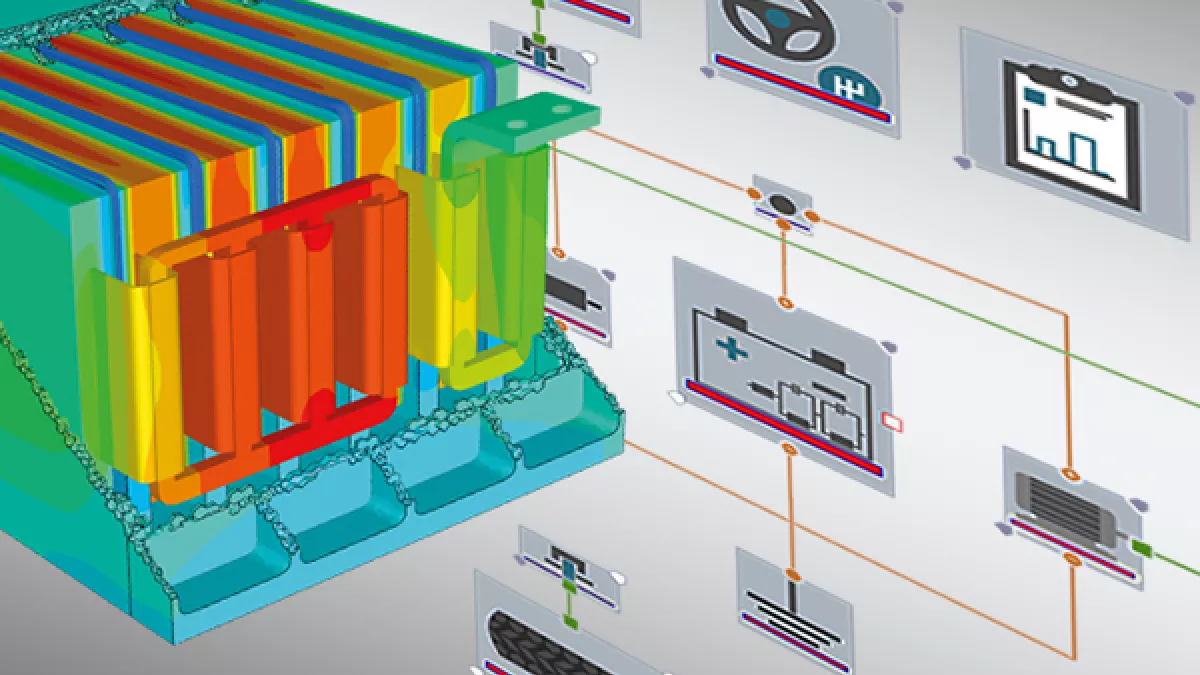

Battery Simulations

Our second very promising utilization of the tools is mainly with CRUISE™ M and Fire™ M software, tools that align perfectly with our ongoing research in battery systems engineering. Our current focus is on the electro-thermal simulations of battery systems, integrating temperature-dependent electrical models with either detailed 3D or 1D thermal models of battery systems. A key goal of ours is to enhance the scalability of these simulations, applying model reduction methods to transition from detailed cell-level analysis to comprehensive system simulations of entire powertrains within vehicles.

We are in the process of wrapping up an internal research project dedicated to this area, aiming to establish a foundational and collective understanding of the subject. The upcoming Horizon Twinning project, “FreeTwinEV”, represents an exciting continuation of this work. This collaboration, involving the Linz Centre of Mechatronics and the University of Twente, will concentrate on the modeling and simulation of battery systems in electric vehicles. The project aims to create digital twins of these systems, leading to enhanced monitoring and understanding of their real-world counterparts.

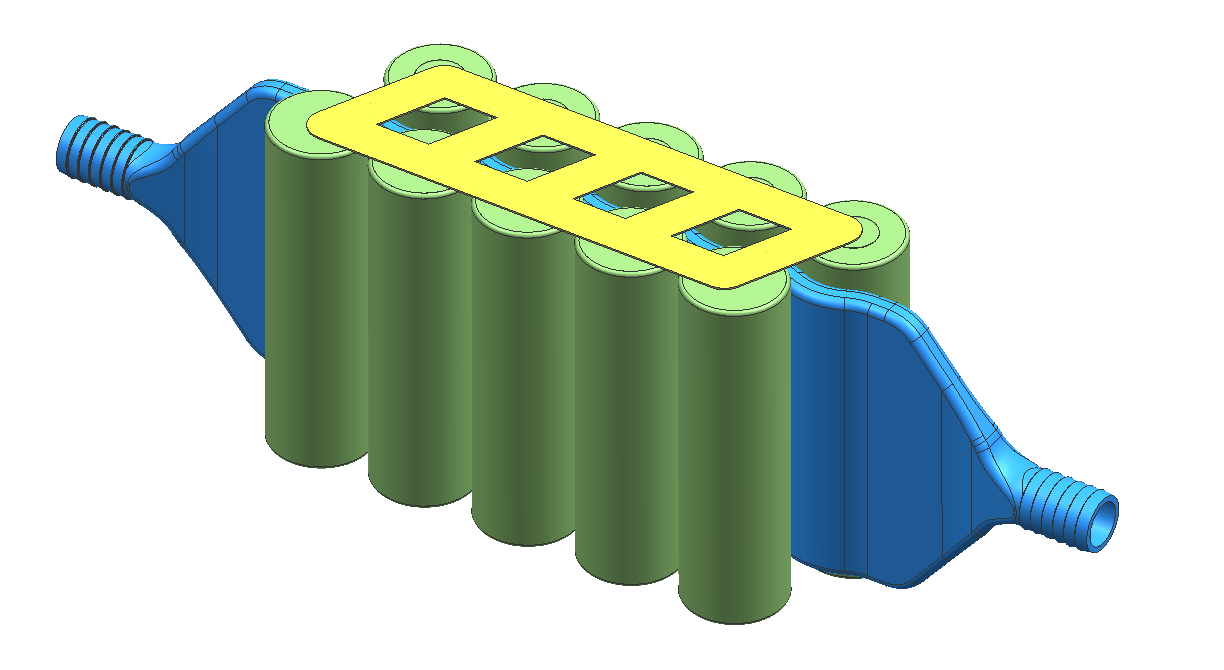

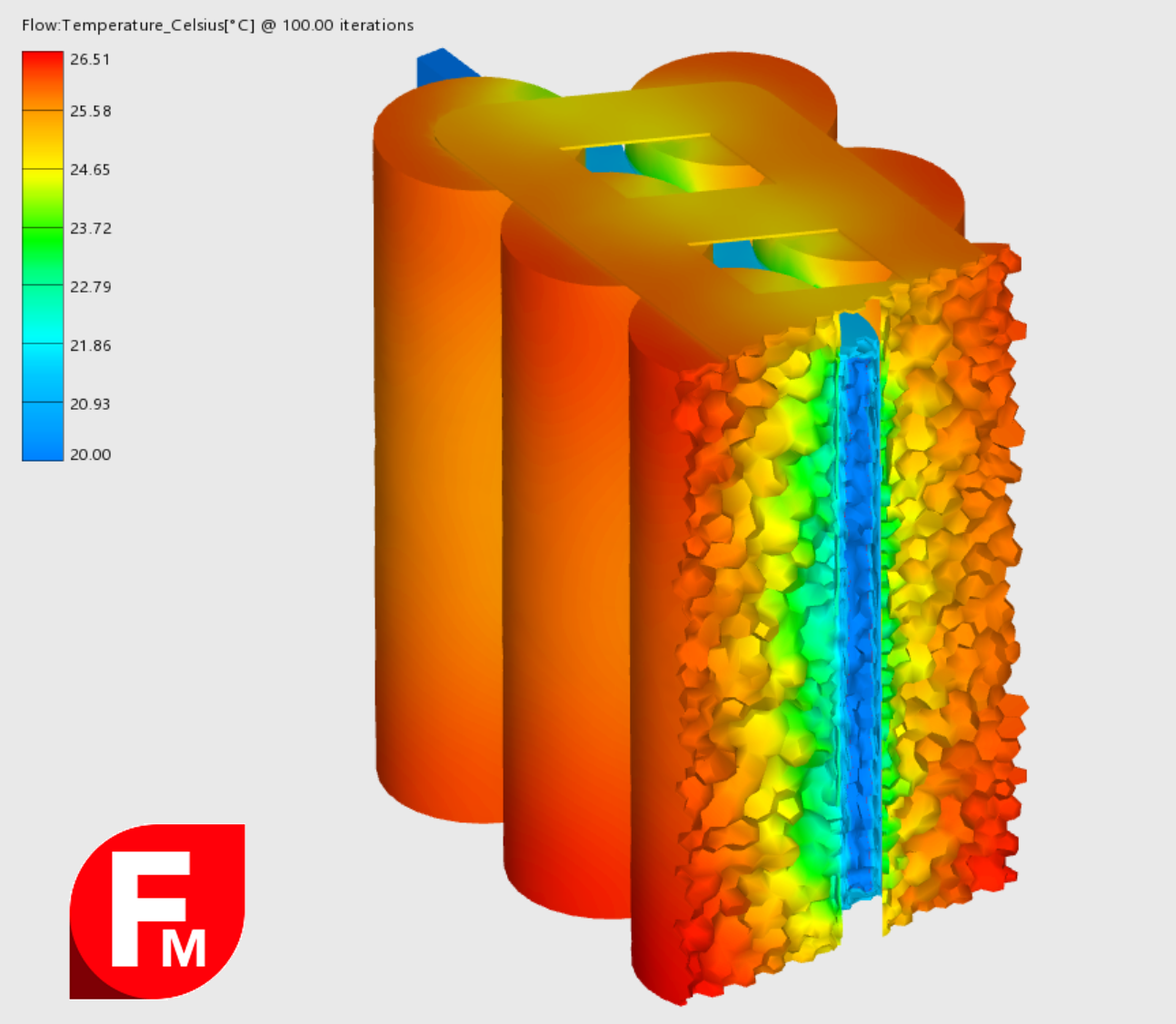

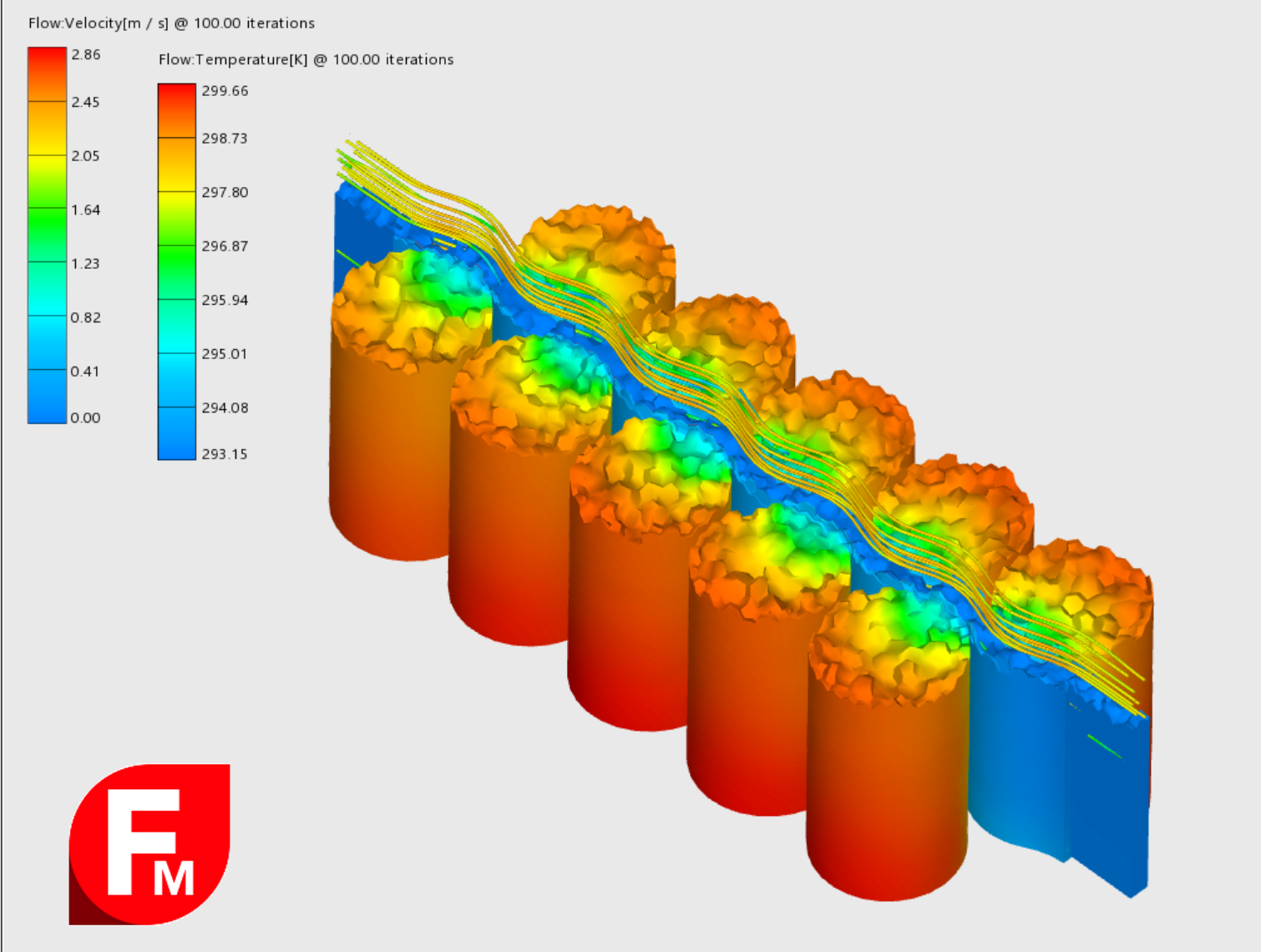

Our preliminary tests with AVL software have confirmed its very good suitability for our needs, particularly in terms of co-simulation capabilities and model scaling. On figures, you can see a basic battery module we've designed for initial methodology validation, simulated using Fire™ M. Moving forward, we're in the stages of manufacturing this module, employing aluminum 3D printing techniques for the cooling components, with plans to validate the simulation outcomes against real-world performance.

We are immensely grateful to AVL for their generous support through the provision of these simulation tools, which look very promising for our usage. We look forward to continuing this partnership and further exploring the potential of AVL's simulation software in shaping the future of automotive engineering education.

Visit the AVL website and find about all their solutions spanning beyond simulation – engineering, development, testing and much more: https://www.avl.com/en

- Log in to post comments